Professor Dina Peterson, Director of the Indiana University School of Medicine’s Diagnostic Sonography Program, PoCUS manager, and Clinical Radiology professor, didn’t originally think of 3D printing when she visited the Ruth Lilly Medical Library’s Makerspace. In fact, her original intention was to use the Makerspace’s button maker to create buttons for her students to wear, indicating they’d successfully completed a course. While creating the buttons with the help of Makerspace Lab Manager, Cassandra Jones, and Assistant Lab Manager, Amanda Papandreou, Professor Peterson noticed the 3D printer available – and had an idea. She asked if it was possible to create a 3D printed liver that could be divided into its 8 segments and assembled using magnets. When teaching about the liver, students sometimes struggle with understanding the segments. A segmented 3D model would be a fantastic teaching aid.

Cassandra and Amanda went straight to work looking for a model that would work for Professor Peterson. Within five minutes, a suitable 3D model was found on Thingiverse.com, a popular 3d model repository that has over 1 million free 3D models. The model was approved by Professor Peterson and two weeks later, it was a physical reality. When Professor Peterson arrived to see the 3D printed liver for the first time in person, Amanda assisted her in gluing in the magnets. The magnet insertion process took roughly an hour and a half and later that day, after the glue had fully dried, Professor Peterson was able to take the segmented liver model back to her office with her.

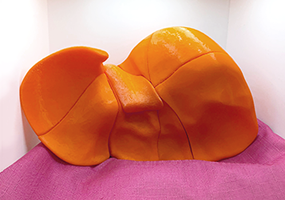

The segmented liver was printed on one of the RLML Makerspace’s seven 3D printers, the Raise3D Pro 2 (fondly nicknamed Edna), using Orange PLA supplied by Professor Peterson for the purpose of this project. PLA (polylactic acid) is a thermoplastic made from sugars and it is the most used 3D printing material currently available. The total amount of material used for this project was 561 grams of filament – plus the magnets which Professor Peterson supplied. Total print time was 62 hours 40 minutes (2 days 14 hours and 40 minutes).

The segmented liver was printed on one of the RLML Makerspace’s seven 3D printers, the Raise3D Pro 2 (fondly nicknamed Edna), using Orange PLA supplied by Professor Peterson for the purpose of this project. PLA (polylactic acid) is a thermoplastic made from sugars and it is the most used 3D printing material currently available. The total amount of material used for this project was 561 grams of filament – plus the magnets which Professor Peterson supplied. Total print time was 62 hours 40 minutes (2 days 14 hours and 40 minutes).

Today, Professor Peterson is happy with the results, "Liver segmentation can be difficult for the learner to visualize because they often learn these segments from a 2D picture. This 3D segmented liver model helps students understand and visualize the segments and their anatomic relationship to each other.”

For more information about resources in the Ruth Lilly Medical Library’s second-floor Technology Corridor – including the Nexus Lab, 3D printers, Virtual Reality headsets, and more – visit https://library.mednet.iu.edu/makerspace/.